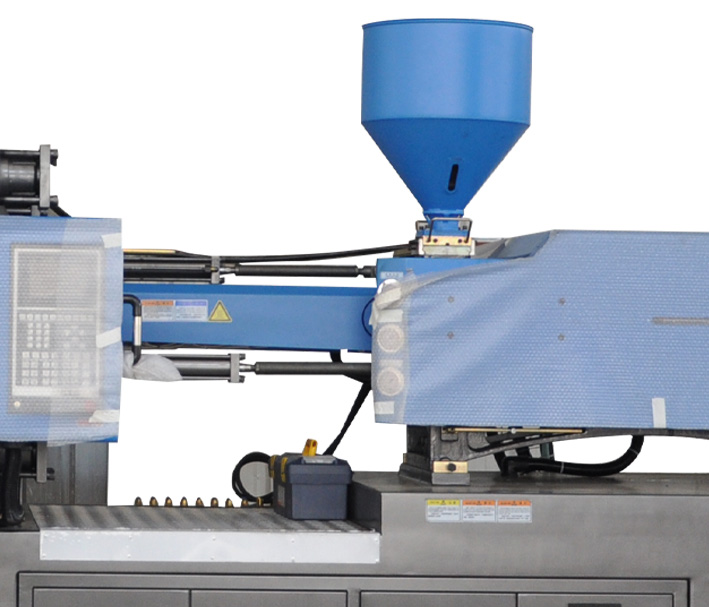

Injection Molding Machine

SKYM SKY Machinery manufacture machines from 100T to 2000T, injection weight from 50g to 10000g, more than 30 different model machines, over 1500 sets machine output ability yearly. Due to continually developing innovation and technological improvement, our machines has exported worldwide, with a good reputation all around world.

Our injection Molding Machine uses proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock,the computer is imported from Industry family.The LCD displaying screen with high clarity has Chinese and English language to use.Close-loop PID temperature control with the advantage of high precision.The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators's safety.

Product name: Injection Molding Machine

High Efficiency Energy Saving Injection Molding Machine:

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

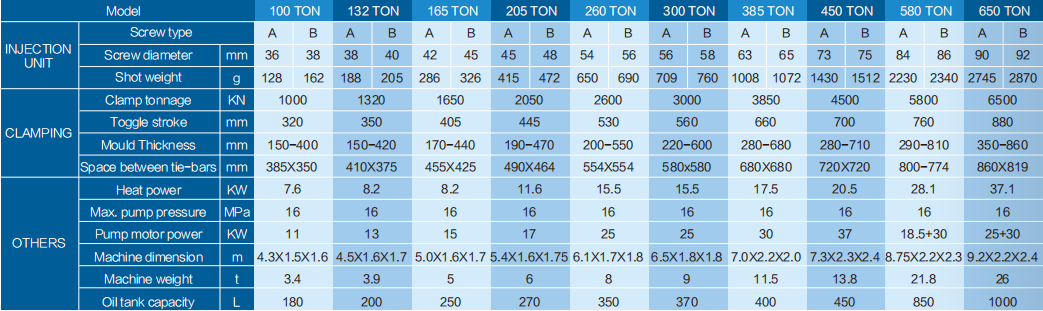

Products Parameter

Machine Details

Injection Unit

-BaIanced double injection cylinder technology makes screw to have evenly distributed force during fast injection,

-Five-star Hydraulic motor with big torque.

-Ensure the excellent plastic molding condition.

-Research and develop different screws according to different injection condition, suitable for the progressive demand and greatly improve the injection quality.

-There are three or four screws and barrels with optimal design, respectively, nitride, hard plating, dual-metal, which is suitable for different processes of a variety of plastics. and the choice of product.

-Two-guided guided bar supports, double-balanced rapid injection.

-The high-torque hydraulic motors offer a stable plasticizing capacity, highprecision electronic device position detection enable accurate measurement.

- Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

- Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, anti- drooling and automated auto purge.

- Expected to prevent cold-start function to ensure that the screw, Liao Tong will not be harmed.

-Stability of the injection unit.

Clamping Unit

-5-point twin toggle clamping system by modular optimization software designing.Strong clamping with rapid and stable, to meet the strict clamping condition.

-Mold height adjustment by hydraulic driven gear system with rapid and stable.

-Automatic mold height adjustment as per the setting clamping force(optional).

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open,the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy

Control Unit

- Imported computer special for Injection Molding Machine with multiple functions and precise control processing.

- World famous electrical components and high quality circuit hardware with stable and reliable running.

- A variety of text can be switched.

- Manual, semi-automatic and fully automatic mode.

- To provide EUROMAP robot interface.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement

FAQ

1. A: Are you factory?How many workers do you have?

B: Yes,we are factory. our factory is located in zhangjiagang near from shanghai. We have about 50 workers in our factory.

2. A: What about after sale service?

B: 12months of electrical part and 18months of mechanical part after machine installed and running normally.

3. A: What about installation?

B: Our engineer can be sent to your country. but customer should pay the air tickets and 100usd as salary per person per day. besides, customer should arrange the accommodation for them during the trip.

4. A: What do we do if we encounter problem about the machine ?

B: Show us the picture or video of the problem. If the problem is from small machine, we will send you solution by video. If the problem is from large machine, our engineer will go to your factory (customer will pay the fee during the trip).

5. A: How can you control the quality and delivery?

B: All our machines will be tested before packaging. wooden packaing is strong and safety for long delivery.