Juice Filling Machine

-

Rinser

Bottle clip equipped with efficient spray on nozzle.The extrusive droplet with 15 angleensures to wash all side of the bottle. -

Filler

The filling valve material is SUS304.The filling system has liquid level automatic control.Filling valve elevator, after filling valve contact the bottle neck, it starts to fill. -

Capper

The magnetic torque is used for screw capping.The power of screw capping can be adjusted without steps.The power of the scr

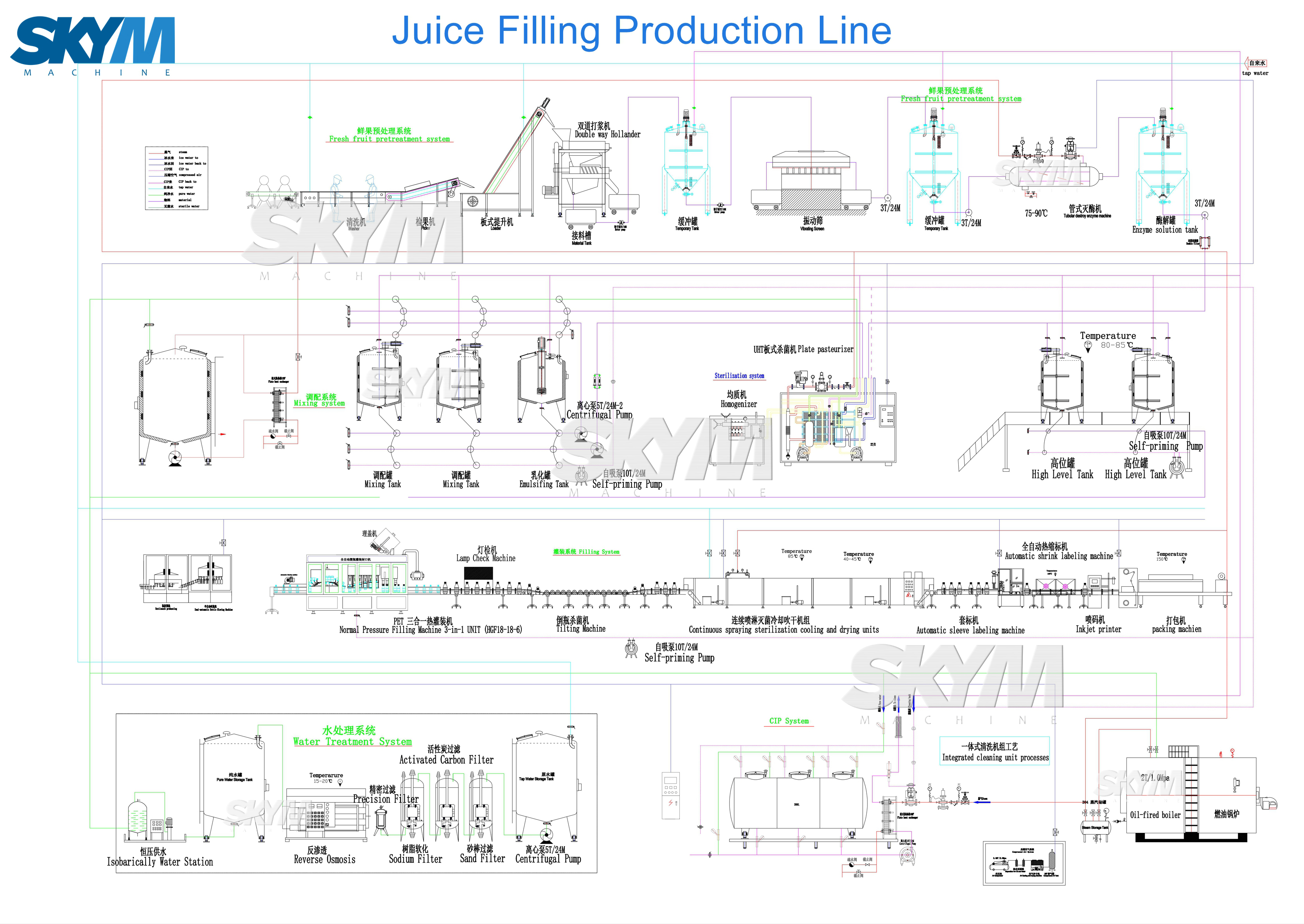

Hot filling technology can expand production and packaging opportunities for juices, nectars, soft drinks, isotonics and teas. No matter your beverage type, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

With 15 years of hot filling experience, we continue to lead the industry with more than 1,00 proven Skymachine Hot Fill

solutions worldwide. Over the last thirty years, we have significantly reduced the weight of heat-resistant bottles while

retaining their durability and improving design opportunities.

One partner for all your needs.

A complete hot fill line solution from Skymachine Machine lets you optimise performance and make more informed decisions across the lifetime of your line. With everything centred around one supplier, you get wide-ranging expertise, equipment and ongoing services to evaluate your entire project. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and more.

Hot Fill Lines is a unique PET packaging solution offering a great alternative for hot-filled beverages in PET bottles. It expands the opportunities of product premiumisation and revenue generation with no compromise on packaging performance and the consumer experience. This innovative solution is addressing the single serve market of Hot fill (juice, nectar, soft drink, isotonics, tea) filled in PET bottles up to 1.2L at a temperature of 85-88°C.

Technical Characters:

1,Full filling is to avoid bottles from sinking after the bottles cooling off, and to decrease dissolved oxygen to the utmost

extent.

2,Reasonable structured storage hopper an material supply system keep material in the constant flow speed, constant pressure and without frothing. Usually high position tank is adopted.

3,The storage hopper has the characteristic of gas dischanrge, full sealing and temperature detecting, in moderate and high speed production line, the materical distributor replaces the big liquid tank to realize the complete CIP.

4,Sanitary filling head system is of umbrella structure, high filling speed.

5,Prefect filling temperature control system.

6,Return tank system have the function of supplying the material automatically.

7,Perfect CIP system.

|

Juice Filling Machine |

|||||||

|

Model |

RCGF 14-12-5 |

RCGF 16-16-5 |

RCGF 24-24-8 |

RCGF32-32-10 |

RCGF40-40-12 |

RCGF50-50-15 |

RCGF60-60-15 |

|

Bottle specifications(mm) |

200ml To 2000ml |

||||||

|

Capacity (500ml/bottle/hour) |

3000-4000 |

5000-7000 |

6000-8000 |

8000-10000 |

12000-15000 |

15000-18000 |

18000-25000 |

|

Power supply(kw) |

2.42 |

3.12 |

3.92 |

3.92 |

5.87 |

7.87 |

11.37 |

|

Overall dimension(L*W*H)MM |

2360×1770×2700 |

2760×2060×2700 |

2800×2230×2700 |

3550×2650×2700 |

4700×3320×2700 |

5900×4150×2700 |

6700×5160×2700 |

|

Weight (KG) |

2600 |

3500 |

4800 |

6500 |

10000 |

12000 |

15000 |