Water Filling Machine

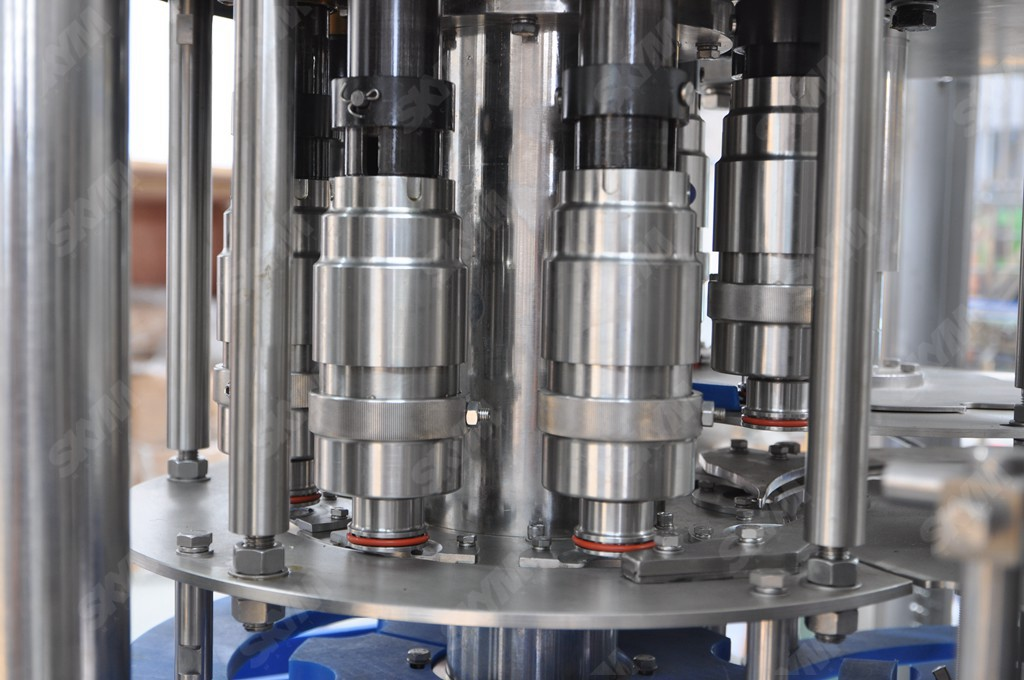

This CGF series water filling machine adopts bottle neck holding transmission technology to realize fully automatic rinsing,filling and capping.Most elements of the electrical system employ famous brand advanced products.Each machine element that contacts with the liquid is made of high quality stainless steel.They obtain the advantages of good abrasive resistance,high stability,low failure rate,etc The quality of the equipment reaches the international advanced level

Machine Characteristics:

1.Using the wind sent access and move wheel in the bottle directly connected technology;Canceled screw and conveyor chains,this enable the change the bottle-shaped become easier.

2.Bottles transmission adopt clip bottleneck technology,bottle-shaped transform not need to adjust the equipment level,only change relater the curved plate,wheel and nylon parts is enough.

3.The specially designed stainless steel bottle washing machine clip is solid and durable,no touch with the screw location of bottle mouth to avoid secondary pollution.

4.High-speed large gravity flow valve filling valve,filling fast,filling accurate and no liquid lose.

5.Spiraling decline when output bottle,transform bottle shape shape no need to adjust the height of conveyor chains.

6.Host adopt advanced PLC automatic control technology,the key electrical components from famous company such as Japan,France Schneider

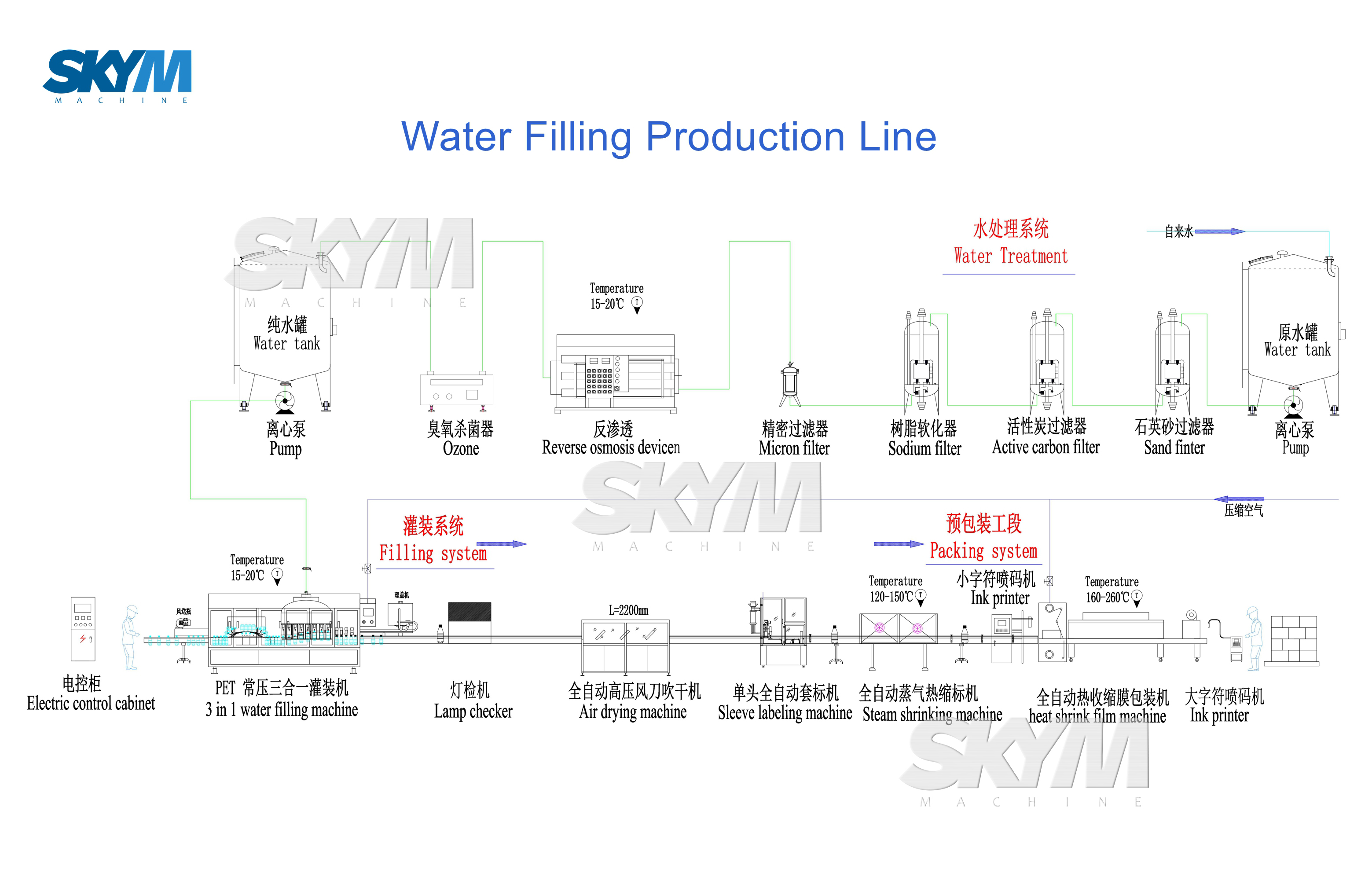

Flow Chart

A.Bottle production line PET Resin-Injection moulding machine-Bottle blowing machine-PET bottle

B.Water treatment system Raw water-Pump-Silica sand filter-Carbon filter-Water softer-Reverse Osmosis-UV sterilizer-Ozone generator-Finished water tank

C.Filling&Packing part Bottle unscrambler-Air conveyor-Washing,filling,capping 3 in 1 machine-Light checker-Blow dryer-Dater printer-Labeling machine-Packing machine-Stock

The rotary wheel is a fully stainless steel welded structure.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

The rinser is driven by driving system positioned inside machine frame via gear transmission.

Transfer starwheel

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

Rotary wheel fully made of stainless steel SUS 304.

Gravity filling method.

Filling valves are made of SUS304.

Filling valves are reasonably structured with accurate filling.

Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Level of cylinder is controlled with float-ball.

Filler is driven through gears inside the machine frame.

Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck.

The equipment is designed and used the technology of AROL from Italy, most advance technology in the world, developed with the experience of asepsis filling machine.

Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

The capper is equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

|

Model |

CGF14-12-5 |

CGF16-16-5 |

CGF24-24-8 |

CGF32-32-10 |

CGF40-40-12 |

CGF50-50-15 |

CGF60-60-15 |

|

Capacity(500ml/bottle/hour) |

3000-5000 |

6000-8000 |

8000-12000 |

12000-15000 |

16000-20000 |

20000-24000 |

25000-30000 |

|

Suitable bottle diameter(mm) |

Φ=50-100 H=170-330 |

||||||

|

Power Supply(KW) |

2.42 |

3.12 |

3.92 |

3.92 |

5.87 |

7.87 |

11.37 |

|

Overall dimension(L*W*H)mm |

2360x1770x2700 |

2760x2060x2700 |

2800x2230x2700 |

3550x2650x2700 |

4700x3320x2700 |

5900x4150x2700 |

5770x5290x2700 |

|

Weight(Kg) |

2500 |

3500 |

4200 |

5500 |

6800 |

7600 |

9800 |