-

Efficient preform supply system

Efficient preform supply system

Fully automated in embryonic germ institutions, not only to achieve the rapid and efficient in embryonic germ action, save labor costs, and further improve the stability of the whole equipment working process, reasonable embryo of sensors mounted on the track when the embryo that lack of preform, preform from the hopper automatically enter the embryo system, and USES the ChanDaoJin embryo, effectively solve the abrasion problem between embryo and preform. -

Servo preform splitting system

Servo preform splitting system

The embryo is divided by equidistant servo motor. The stroke and speed of the servo motor can be adjusted simply by adjusting the parameters on the operating table. The complex process can be completed by digitalization, which is safe, fast and accurate. Compared with the traditional multi-channel embryo division and cylinder embryo division, the single-channel embryo division method controlled by servo motor has faster speed and more accurate position. -

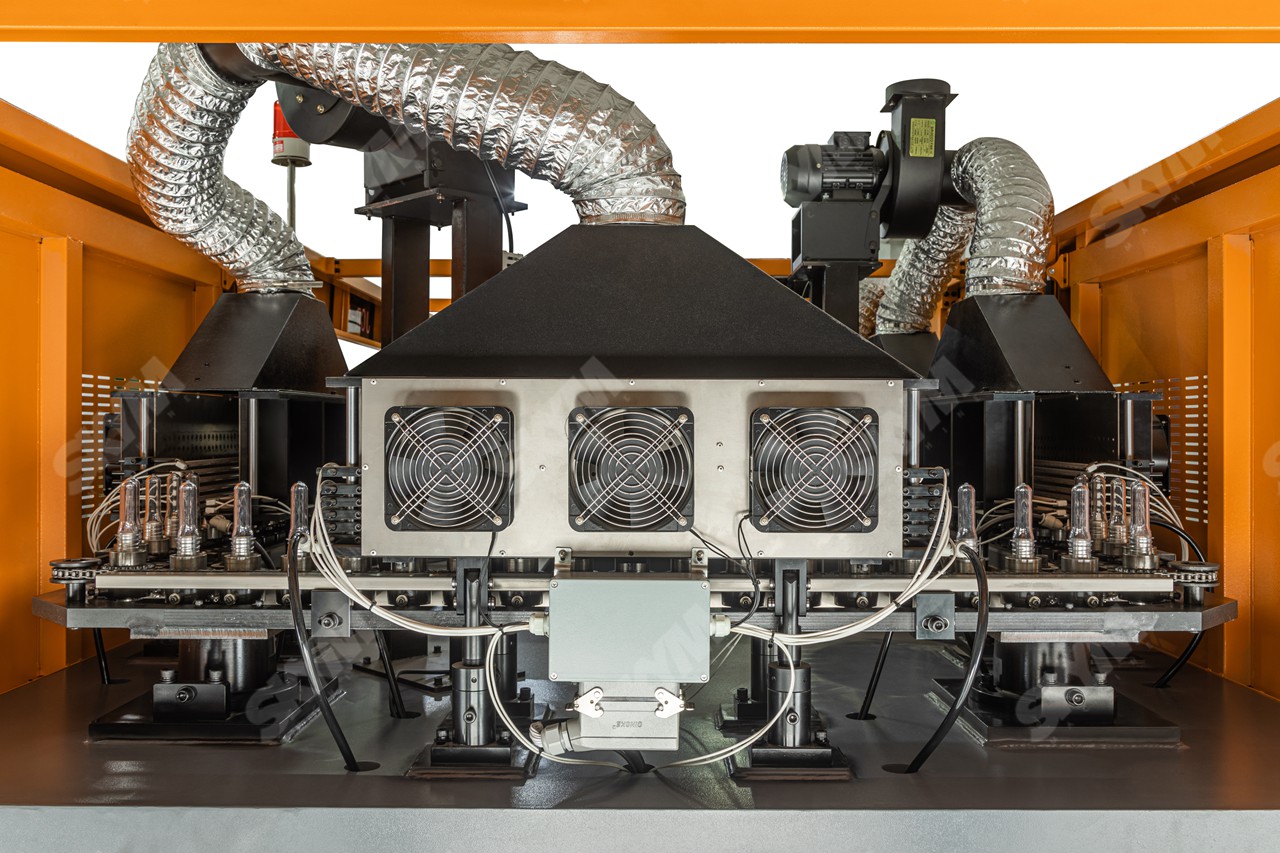

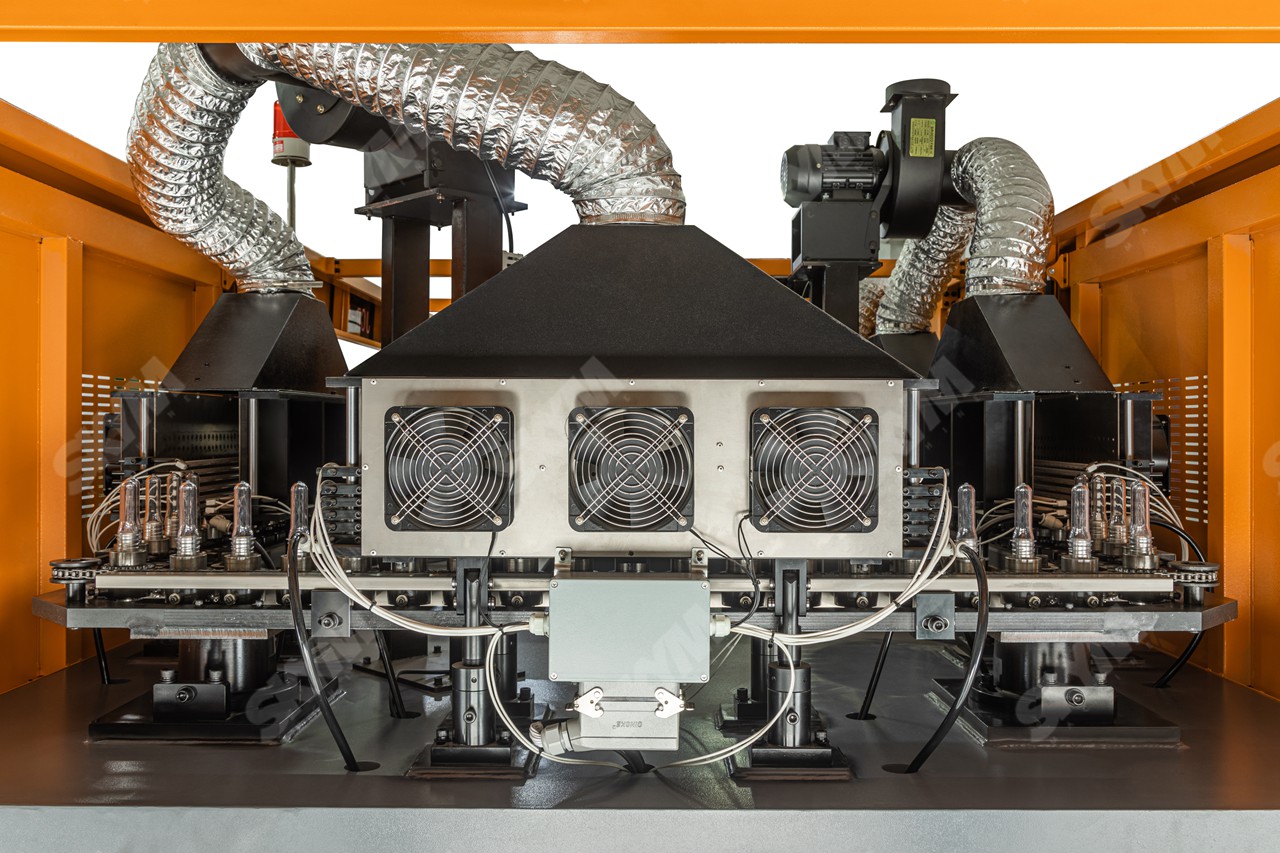

Intelligent heating system

Intelligent heating system

Using infrared lamp to penetrate the preform heating, so that the preform stretching more uniform, high transparency; Equipped with imported mirror aluminum plate, make full use of the heat energy of the lamp, shorten heating time, reduce energy consumption and improve production capacity. And each layer of each tube can be separately adjusted temperature, according to thecustomer's different tube embryo up and down, before and after adjustment. -

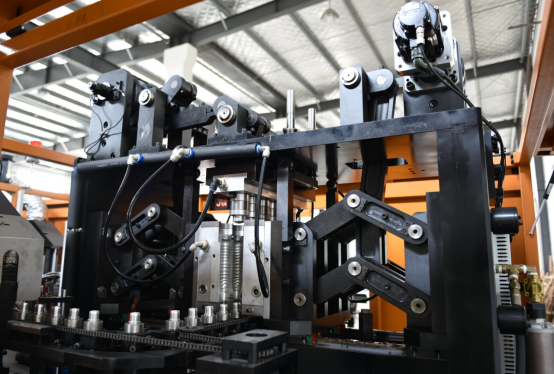

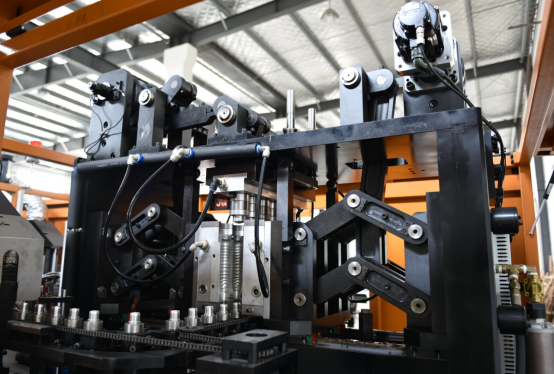

Servo clamping system

Servo clamping system

The clamping system is driven by a servo motor and driven by a mechanical connecting rod. The die and the bottom die are closed synchronously by a servo motor. The back of the mold frame is equipped with high pressure increasing plate, high pressure locking mold, effectively reduce the visibility of the finished bottle closing line, ensure the quality of the bottle. The mold adopts a drawer structure, which is easy to replace the mold, and the operator can complete it within half an hour. -

Man-machine operating system

Man-machine operating system

Skymachine high intelligence blowing Machine, simple and convenient operation. Color touch screen in both Chinese and English, with perfect monitoring and induction Settings, with fault diagnosis display, automatic calculation report, memory storage and other functions, can always control the production of the equipment.In this way, problems can be found in time and solved immediately, which greatly improves the efficiency of production work. -

Cooling/freezing water circulation system

Cooling/freezing water circulation system

The cooling and heating head device independently developed by Sky Machine company ensures the cooling of the heating head out of the bottle. A cooling channel is arranged under the heating box. When the preform is heated, the cooling channel is used to block the heat of the lamp tube. There is a cold air system under the cooling channel to cool the bottle mouth and protect the mouth from deformation. Chilled water to the mold, rapid cooling mold, improve the productivity efficiency of the machine.

Electric Blow Molding Machine

This electric bottle blowing machine is a linear bottle blowing machine which is developed and researched by the most advanced bottom making technology in the current world and molded through blowing PET(Polyethylene Terepthalate)by high pressure compressed gas.The machine needs a bottle blank appropriate to bottle type.This bottle blowing machine can be used independently for blowing bottles or completion of bottle blowing before filling lines.The machine shows characteristics such as high intelligence,stable and reliable mechanical performance, high production efficiency,low cost and pollution free from intermediate process,it is widely used for production of food,drink,cosmetic and medical vessel.

1.Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2.Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple

maintenance and safety.

3. Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. Manual and automatic methods of operation, human-machine interface control, simple operation.

5. Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. Less than 0.2% scrap rate for finished bottle .

7. The blow molding machine runs stably at high speed and precise positioning.It adopts advanced microcomputer PLC control system, which can be more stable.

8. The production process is all automated, which

has the advantages of low investment, high efficiency, convenient operation, simple maintenance, and safety.

9. Servo transmission system, high positioning accuracy, fast speed, stability and reliability.

10. It is suitable for small and diverse flexible production, with a wide range of applications and in line with customer needs.

11. The efficiency of energy use is improved, and the production capacity per unit time is improved.

12. There are two modes of operation, manual and automatic, with man-machine interface control and simple operation. 13. Servo transmission system, high positioning accuracy, fast speed, stability and reliability.

14. Each mechanical action has a safety self-locking device. When a process fails, the program will automatically switch to a safe state.

15. Heat generation and noise are significantly reduced.

16. The scrap rate of finished bottles of the blow molding machine is less than 0.2%.

|

Classification |

Project |

Technical parameters |

|

Bottle blowing conditions |

Maximum volume of bottle type (ML) |

680 |

|

Maximum diameter of bottle type (MM) |

Φ70 |

|

|

Bottle size (MM) |

Φ18 ~ Φ38 |

|

|

The maximum height of the bottle (MM) |

<240 |

|

|

Model stroke (MM) |

90 |

|

|

Bottom die stroke (MM) |

50 |

|

|

Bottle spacing (MM) |

76.2 |

|

|

Design output (BPH) |

9000 (500ML water bottle) |

|

|

Mold cavity number |

6 |

|

|

Light box heating part |

Heating unit |

4 |

|

Heating lamp layer number |

8 |

|

|

(a) the number of germ tube |

108 |

|

|

Electrical parameters |

Voltage |

380V |

|

frequency |

50Hz |

|

|

Use power |

20~30kw/h |

|

|

Installed power |

72kw |

|

|

Gas source parameters of bottle blowing |

Low pressure pressure |

10kg |

|

Low pressure gas consumption |

1m3/min |

|

|

High pressure pressure |

35kg |

|

|

High pressure consumption |

6~8m3/min |

|

|

Cooling parameters |

temperature |

≤16℃ |

|

pressure |

4kgr |

|

|

flow |

9L/h |

|

|

Equipment weight |

Bottle blows machine |

About 7.5t |

|

Bottle blowing machine size |

Host (L x W x H) |

4500m×2200m×2600m |

|

Embryo machine (L x W x H) |

3200m×2800m×3000m |